PLM vs PIM: Do you need one or both for your product journey?

Choose the right path for your product data

Get guidance tailored to your product journey. Let’s review your needs and map the PLM and PIM setup that fits your business.

Shoppers return products for reasons that should be preventable. The DHL E-commerce Trends 2025 report shows that over half of returns stem from quality or fault issues, and 39% occur because items do not match their images. These patterns point to a deeper problem. Product information breaks down long before it reaches the digital shelf, and teams struggle to keep data accurate as it moves across systems.

Procurement teams face similar pressure. Research published in the Journal of Purchasing & Supply Management shows that suppliers earn greater trust when they maintain detailed, regularly updated product data, supported by credible third-party verification. Gaps in accuracy or validation affect every part of your organization.

Your product stack plays a central role in solving that. This article helps you decide what to use at each stage of your product journey. You will see how PLM (product lifecycle management) strengthens creation, how PIM (product information management) manages commercialization, and how the two systems work together to keep product data accurate from the first specification to every customer touchpoint.

PLM vs PIM: What separates the two systems?

Teams often confuse PLM and PIM because both manage product data, but they serve very different stages of your product journey.

PLM vs PIM

PLM structures the product’s foundation by guiding development teams through controlled specifications, compliant materials, and approved design changes.

PIM builds on that foundation by turning validated data into enriched product content for every selling channel and customer touchpoint.

When PLM and PIM work together, your teams gain a continuous flow of accurate information from creation to commercialization, improving speed, collaboration, and product visibility across markets.

What each system does

What is PLM?

PLM manages creation. It organizes specifications, design files, technical details, and approval steps that shape the product before it ever reaches the market. R&D, engineering, quality, compliance, and procurement rely on PLM to inform early decisions and maintain accuracy throughout development.

What is PIM?

PIM manages commercialization. It structures the product information your customers and channels need, centralizes updates, and distributes content across e-commerce, retail, marketplaces, and partners. Merchandisers, marketers, sales teams, and channel managers use PIM to keep every listing accurate and consistent.

PLM vs PIM: Side-by-side comparison

| Category | PLM | PIM |

|---|---|---|

| Primary purpose | Manage product development and specifications | Manage product information for sales, marketing, and distribution |

| Users | R&D, engineering, product management, compliance, procurement | Merchandisers, marketers, e-commerce teams, sales operations, channel managers |

| Data focus | Materials, components, measurements, part numbers, compliance data, Bill of Materials | Titles, descriptions, attributes, rich content, images, documents, channel-specific formats |

| Workflow | Design iterations, approvals, testing, lifecycle updates | Content enrichment, localization, channel formatting, publishing, and syndication |

| Output | A complete, validated product ready for commercialization | A complete, accurate product story prepared for every channel |

| Strength | Controls internal accuracy during creation | Controls external accuracy during market activation |

| Best used for | Engineering change control, technical governance, and early lifecycle decisions | E-commerce accuracy, marketplace readiness, partner content delivery, omnichannel performance |

PLM and PIM solve different problems at different stages. Use the PIM Buyer’s Guide to decide where PIM fits in your stack.

When should your team use PLM or PIM?

Choosing between PLM and PIM depends on what your teams need to accomplish. Each system solves a different part of the product journey, and your priorities make the decision clear.

Use PLM when your focus is on creation

PLM is the right choice if your teams manage:

- Product design or engineering changes

- R&D work that shapes product specifications

- Supplier inputs or component updates

- Manufacturing planning or production readiness

- Technical compliance requirements

These tasks rely on precise, validated information that must stay consistent from the first draft of a product through every internal approval.

Use PIM when your focus is on commercialization

Choose PIM if your teams need to manage:

- Large product catalogs and frequent updates

- Channel-specific requirements for retailers and marketplaces

- Localization, translations, or region-specific assortments

- Rich content, imagery, and digital asset coordination

- Product experiences across e-commerce and in-store journeys

If your priorities are strong visibility, faster time-to-market, and accurate product content across every sales channel, a PIM solution provides the structure and control required for scale.

Use both when your teams want a connected product journey

Many organizations reach a point where creation and commercialization must move in sync. PLM protects technical accuracy. PIM turns that accuracy into customer-ready content. When the two systems work together, you reduce rework, strengthen data quality, and support every team responsible for bringing products to market.

How do PLM and PIM work together?

Integration becomes essential once your product mix grows, regulations tighten, or new channels introduce extra data demands. A connected PLM and PIM setup gives you the structure to manage higher volumes of updates, a more complex assortment, and the level of accuracy required across global markets.

How PLM and PIM connect across the product journey

| Product stage | Role of PLM | Role of PIM |

|---|---|---|

| Concept & design | Capture requirements, components, and early specifications | No involvement yet; waits for validated data |

| Development & testing | Manage engineering changes, testing data, and compliance inputs | Prepare an early structure for future product records |

| Pre-launch readiness | Finalize specifications and hand over approved product data | Enrich content, build attributes, organize assets |

| Launch & activation | Maintain technical records for any post-launch updates | Publish listings, syndicate to channels, manage local variations |

| Growth & lifecycle updates | Track changes across materials, components, and versions | Update product content, support new markets, and new assortments |

What benefits do PLM and PIM deliver for your business?

Different teams value PLM and PIM in various ways. The impact becomes clearer when you map benefits to the realities of manufacturers and retailers.

Benefits for manufacturers

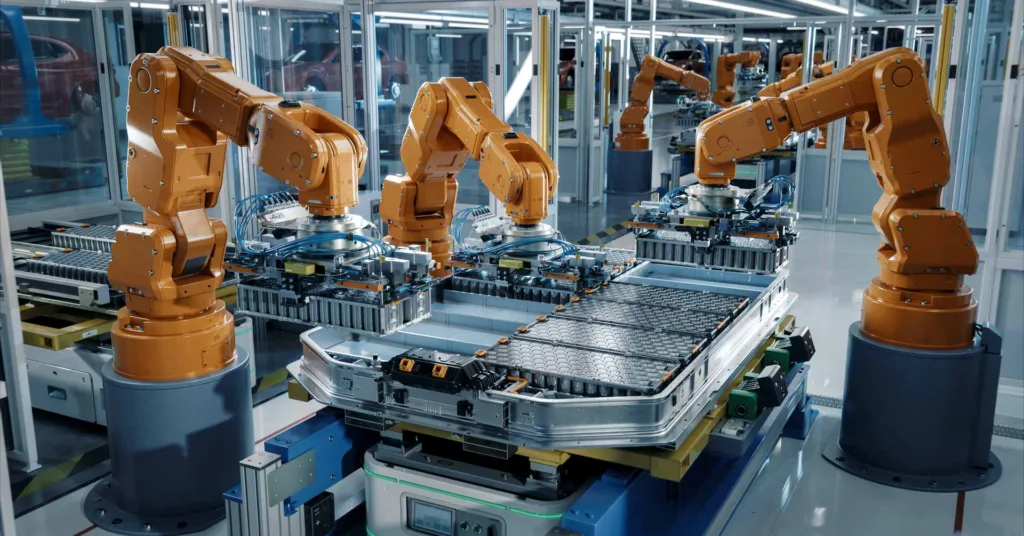

Manufacturers depend on accurate specifications, clean change control, and tight coordination between engineering, quality, and compliance. PLM gives them the power they need early in the lifecycle, while PIM strengthens everything that follows once the product is ready for the market. Learn about the importance of accurate product data for brands pursuing sustainable and circular manufacturing.

How PLM helps manufacturers

- Protects product quality through structured design and specification management

- Reduces time spent on engineering changes and technical iterations

- Strengthens internal compliance and documentation

- Keeps development teams aligned on the latest version of every component

How PIM helps manufacturers

- Prepares rich product information for every sales and distribution channel

- Reduces returns by improving product accuracy, imagery, and detail

- Improves conversions with consistent, channel-ready content

- Supports global expansion with scalable enrichment and localization

These capabilities matter even more for manufacturers with expanding catalogs or rising commercial demands, making manufacturing PIM a key part of the product journey.

Benefits for retailers

Retailers need complete, accurate, and trusted product information to deliver strong customer experiences across e-commerce, marketplaces, and stores. PLM provides upstream clarity, while PIM ensures that customer-facing content is consistent wherever your products appear.

How PLM helps retailers

- Ensures technical details and specifications arrive validated and ready for activation

- Improves downstream accuracy by reducing gaps between product development and merchandising

- Minimizes errors that lead to customer dissatisfaction or compliance issues

How PIM helps retailers

- Enables consistent, enriched content at scale across every channel

- Supports rapid onboarding of new products and suppliers

- Improves visibility, search performance, and conversions

- Allows merchandising and e-commerce teams to adapt content quickly for promotions or regional needs

Retailers with fast-moving assortments or multi-channel strategies gain measurable value from PIM, making Retail PIM essential for growth.

How Inriver fuels your product journey

Inriver gives your teams the clarity and control needed once PLM locks in the technical details. Product records move cleanly from development to commercialization, and every channel receives accurate, enriched content without rework or duplication. The platform becomes the single place where product information turns into performance, supporting everything from syndication to regulatory readiness.

How PLM and Inriver work together

| Workflow stage | What PLM provides | How Inriver strengthens it |

|---|---|---|

| Technical creation | Specifications, materials, measurements, compliance inputs | Builds the initial product record and prepares the structure for enrichment |

| Version control | Engineering updates and change management | Syncs updated details into customer-ready content fields with full traceability |

| Quality & validation | Approved data for components and final products | Converts technical accuracy into attributes, descriptions, and media that improve conversions |

| Pre-launch readiness | Final development handover | Enables enrichment, localization, channel formatting, and readiness checks |

| Channel activation | No direct role | Publishes accurate product information across e-commerce, marketplaces, retail partners, and internal systems |

| Lifecycle improvements | Ongoing updates from engineering or supply chain | Cascades new data across every channel and keeps product content aligned over time |

Many brands already rely on Inriver to turn complex product data into customer-ready content across every channel. Mercury Marine is one of them.

– Mary Jo Mullen

Product Data & Analysis, Mercury Marine

Strengthen your product journey

Bring clarity to every stage of your product lifecycle with the right combination of PLM and PIM. PLM secures the technical truth behind development, while Inriver turns that accuracy into enriched, channel-ready content that improves visibility, conversions, and compliance.

Your teams can move faster when the whole journey is connected, especially as your product mix expands and channel demands grow.

If you want a closer look at how PIM powers the full journey, or you need guidance on choosing the right PIM solution, our team can walk you through the approach that best supports your business.

See the Inriver PIM in action

Inriver offers the most comprehensive PIM solution on the market, built for speed, scale, and complexity. Let an Inriver expert explain how the Inriver PIM can turn your product data flows into a sustainable revenue stream.

- Get a personalized, guided demo of the Inriver platform

- Have all your PIM questions answered

- Free consultation, zero commitment

Thanks for reaching out!

We’ll be in touch soon.

Please try again in a moment.

PLM vs PIM: Frequently asked questions

The key difference between a PIM system and PLM software lies in their focus on different stages of the entire lifecycle of a product. PLM software is primarily concerned with managing the product development phase, including design, engineering, and compliance, which contributes to operational efficiency by streamlining internal processes. On the other hand, a PIM system focuses on the commercialization of the product, ensuring accurate product information is available for sales, marketing, and distribution channels.

PIM integration facilitates collaboration by providing a centralized knowledge base where all product–related information is stored and accessible to various teams, including marketing, sales, and customer support. This integration ensures that teams have accurate product information at their fingertips, reducing the chances of discrepancies and improving communication across departments.

While a PIM system and PIM software are often used interchangeably, they can serve slightly different use cases depending on the organization’s needs. A PIM system generally refers to the broader infrastructure or framework used to manage product–related information across various channels. PIM software, on the other hand, refers specifically to the tools and applications within that system designed to manage, clean, and distribute accurate product information. Both are integral to ensuring that the right information reaches the right audience, but the specific use case will determine how they are implemented and utilized within an organization.

You may also like…

author

Anders Josefsson

Director, Product Management, inriver

As the Director of Product Management, Anders leads a team of product managers, designers, and product marketing and launch managers. Their passion for understanding customer needs and pain points drive their focus on ideating, creating, and bringing to market viable solutions that meet those needs. Anders has 25 years of experience from product innovation in various industries and markets, and this experience comes in handy when creating the next chapters of inriver's product journey.

Read more