The role of manufacturing in a circular economy

blog

April 5, 2023It might be the hottest term in sustainability, but what does the circular economy mean for manufacturing? And what benefits does it bring?

The circular economy is helping to change the way we think about the products we buy – and the waste we create. Instead of the linear process that has been business as usual for centuries, circularity looks to make the landfill a thing of the past, or at least less of a thing in the future.

Manufacturing has a crucial role to play in this shift towards a more circular economy. But just how feasible is circularity in manufacturing? And what do manufacturers need to be aware of as they seek to bring their linear processes into a more circular future? Let’s find out.

The move towards circularity in manufacturing

Nowhere is the idea of making better use of resources more crucial than in the global manufacturing sector. Whether they make tennis rackets, televisions, or transistors, manufacturers around the world are embracing circularity. This reduces their own environmental impact and provides a better experience for their sustainability-conscious customers.

For manufacturers, circularity is a significant shift in focus. From simply producing goods and services to creating items that are high quality and durable, the difference is clear. By designing products with reusability in mind, manufacturers can massively reduce their consumption of raw materials. They can also make a significant dent in the amount of waste related to their operations, including emissions.

How can we make manufacturing more circular?

Acknowledging the need for more circularity in manufacturing is one thing. Making it a reality will require manufacturers to implement several deep changes to the way they work. Production processes and value chains don’t become circular overnight.

As the manufacturing world shifts towards a circular economy, close collaboration is needed across the supply chain. This is essential to identify viable new material choices, adapt processes, and reduce waste. Facilitating the seamless, transparent flow of product information and other data between suppliers, manufacturers, logistics, and customers is not just something to aim for – it’s essential for bringing fully circular manufacturing to life.

What are the benefits of circularity in manufacturing?

There is no single approach to circularity. However, there are a number of different benefits for manufacturers looking to embrace these new ways of doing business.

Reducing resource use

For many businesses, there are ways to introduce recycled or secondary materials into their manufacturing processes to limit the number of raw materials used. For example, in 2022 Apple increased the amount of recycled tungsten and cobalt used in new products. This is reducing the number of rare earth metals we extract through mining.

Making refurbishment and reusability much simpler

Circularity in manufacturing is thinking about how much the lifespan of an existing product can be stretched, and ways to design longevity into a product. For example, tech giant Philips lets hospitals upgrade equipment by trading in their existing equipment. This equipment is then refurbished and sold again, at more affordable prices.

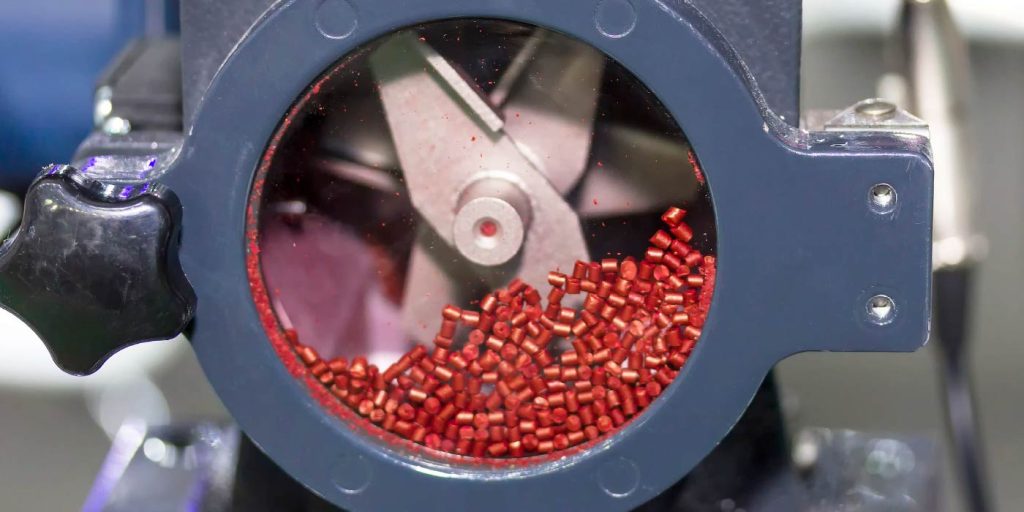

Recycling materials for a wide range of additional uses

It’s also possible for manufacturing companies to convert materials or parts from products at the end of their lives into entirely new ones. Unlike reusing the components in the same application over and over, recycled materials have a potentially much wider range of uses. Take aluminum for example – it is almost endlessly recyclable and can be used in a lot of different ways. In fact, nearly 75% of all aluminum ever produced is still being used today.

Allowing brands to recover value in other ways

Even if you aren’t actively reusing materials to make new products, there are still ways to extend the value of older products. Many businesses are innovating new ways of turning waste into fuel. Converting organic waste into sustainable biogas is a process attracting interest from companies that are not only looking to be more sustainable but also reduce their energy expenditure.

How feasible is a truly circular economy in manufacturing?

Building circularity into manufacturing processes is not going to happen overnight. It is going to take large amounts of investment to upgrade or replace existing infrastructure. Despite a few trailblazers leading the way, circularity remains an expensive and complex challenge for many manufacturers. As tech ecosystems and applications continue to mature, the barriers to entry will keep lowering over the coming years.

There is also a large appetite for circularity from both consumers and governments. The EU has launched its new Circular Economy Action Plan and many others may follow suit. This will likely lead to a growing number of regulations introduced for certain sectors and product categories, such as the forthcoming digital product passports. Soon enough, circularity won’t just be a nice-to-have goal for manufacturers, it’ll be a compliance requirement.

The future of manufacturing in a circular economy starts with data

Foundational for this shift towards circularity in manufacturing is the consolidation of product information from across the value chain. Without the transparency that this consolidation provides, manufacturers will struggle to fully understand how they can expand the lifecycle of their products, and meet demands from consumers, regulators, and more.

To move towards this more sustainable future, manufacturers need to employ the right technology solutions that can help them meet the new demands of the circular product journey. Product information management is an increasingly essential part of product-based commerce, and PIM software provides complete visibility and transparency over all your product data, from sourcing through to end-of-life.

Want to know more about how circularity feeds into other trends driving the future of manufacturing? Read our latest ebook, A new era of opportunity in manufacturing, or book a demo with a PIM expert to find out how inriver can help you meet sustainability demands. You can also learn more about PIM for manufacturing here.

you may also like…

Powering sustainability with PIM

As the world moves towards a more circular future, the need for brands, manufacturers, and retailers to embrace sustainability has never been clearer. PIM plays a pivotal role in this push for sustainability, elevating data transparency to meet demands from consumers, regulators, and stakeholders across the entire product journey.

Brooke Cunningham

Chief Marketing Officer

As Chief Marketing Officer, Brooke is responsible for inriver's end-to-end marketing strategy.

read more